Micro-Tweezers

(by Richard Parke, MEng. Project Student, 2004)

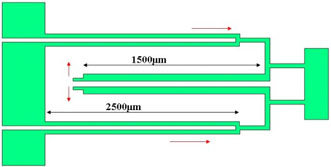

A pair of tweezers shown is formed by formed by two mirrored structures connected alongside each other. The tweezers open when current is applied to the pads, indicated by the red arrows. The movement is induced by hot arm pairs similar to that described for cantilever electrothermal actuators. After fabrication, the beam tweezers were largely affected by stiction. With an applied voltage of 20V the separation of the arms increases to 9.6µm.

Although the video clip above confirms that the tweezers structure works, the actuators’ major downfall is the length of its hot beams. When the length of a beam increases the effects of stiction, heat loss and residual stress become more significant. A long beam has much more surface area than a short beam and it will be less efficient at reaching high temperatures. Also, beam deflection caused by non uniform stress is proportional to beam length. The deflection can be upward or downward depending on the stress gradient in the beam and it greatly reducing the efficient of the actuator.