Microelectromechanical Systems (MEMS) and Devices

During the past decade, considerable effort has been devoted to microelectromechanical systems (MEMS), Silicon micromachining has become a fundamental tool that enables the fabrication of such devices. The technology has evolved from integrated circuit fabrication processes, namely film formation, doping, lithography and etching. In general, silicon micromachining can be subdivided into two categories, bulk and surface machining. In bulk micromachining, three dimensional features and micromechanical devices are realised out of single crystal silicon wafers. In contrast, surface micromachining employs thin-film layers on the substrate surface and generally involves dimensions smaller than those of bulk micromachined devices.

Below is a selection of MEMS structures the QAMEC facility has produced.

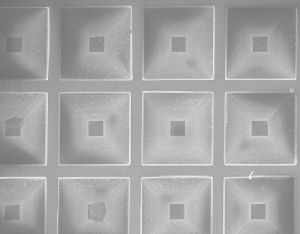

Frequency Selective Surfaces

Frequency Selective Surfaces

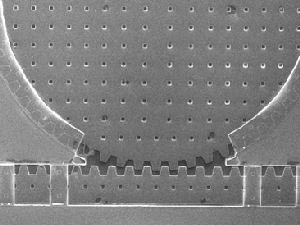

Rack and Pinion

Rack and Pinion

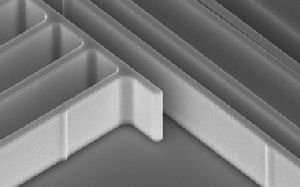

Passive Microfluidics Valve

Passive Microfluidics Valve

Comb Drive

Comb Drive

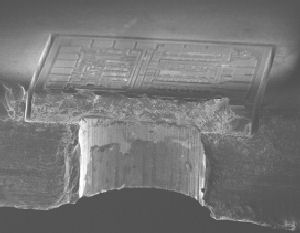

GaAs Embedded Chip

GaAs Embedded Chip

Chemotaxis System

Chemotaxis System

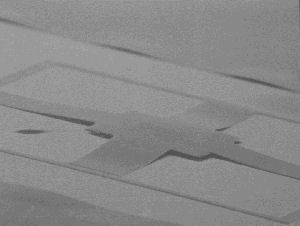

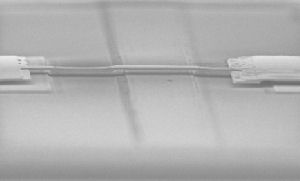

rf Switch

rf Switch

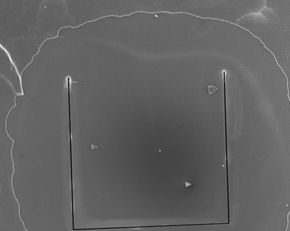

Cantilever for Photoacoustic Sensor

Cantilever for Photoacoustic Sensor

Click here for a short presentation of MEMS research at the QAMEC facilities.