Impact resistance of Ultra High Performance Fibre Reinforced Concrete (UHPFRC)

Planners, architects and engineers are involved in every aspect of the built environment, from airports to hospitals, from motorways to railways, from factories to leisure centres, from houses to offices, etc. They are responsible for providing a safe environment for people to live and work. Abnormal loading on infrastructure is becoming more and more important and this has been highlighted by such terrorist attacks as those on the Twin Towers (the World Trade Center), the Alfred P. Murrah office building and the Khobar Towers. While it would be unreasonable to expect a structure to withstand extremes of accidental loading as may be caused by collision, explosion or similar, it is important that the resulting damage should not be disproportionate to the cause. It follows therefore that a major structural collapse must not be allowed to be caused by a relatively minor mishap which may have a reasonably high probability of happening in the anticipated lifetime of the structure.

Millard, S. G., Soutsos, M. N., Schleyer, G., Mines, R. A. W., and Tyas, A. “Impact and Blast Resistance of Ultra High Performance Fibre Reinforced Concrete (UHPFRC),” EPSRC Grant Ref. No. : EP/D041201/1, April 2006 – March 2009.

Nicolaides, D., Christou, P., Petrou, M., Ioannou, I., Soutsos, M. N., Schleyer, G., Ralph, J., Hadjigeorgiou, K., Zachariou, G., “Mix Design, Mechanical Properties and Impact Resistance of Ultra High Performance Fibre Reinforced Cementitious Composites (UHPFRCCs),” Research Promotion Foundation – Framework Programme for Research.

Technological Development and Innovation 2009-10, Euros: 180,000, Sept 2012 – Sept 2014.

Soutsos, M.; Robinson, D.; Chen, J.; and Rafeet, A., “Numerical modelling of UHPFRC beams under impact load,” Proceedings of the conference on: Concrete for the Modern Age - Developments in materials and process, Military Technological College, Sultanate of Oman, 20-22 November 2017, p. 82 -89.

Soutsos, M.; Robinson, D., and Chen, J.F., “Development of impact resistant UHPFRC,” Proceedings of the 3rd International Symposium on Ultra-High Performance Fibre-Reinforced Concrete (UHPFRC 2017), Montpellier, France, pp. 281 – 290.

He Y., Esmaeeli E., Soutsos M.N. (Sept. 2021) Application of 3D Digital Image Correlation to Capture the Impact Behaviour of UHPFRC Plate. In: Serna P., Llano-Torre A., Martí-Vargas J.R., Navarro-Gregori J. (eds) Fibre Reinforced Concrete: Improvements and Innovations II. BEFIB 2021. RILEM Bookseries, vol 36. Springer, Cham. https://doi.org/10.1007/978-3-030-83719-8_79

He, Y., E. Esmaeeli, and M. Soutsos (August 2020), "Effect of casting method and test setup on flexural characterization of UHPFRC", Civil Engineering Research in Ireland (CERI2020), Cork Institute of Technology, Cork, Ireland.

Nicolaides, D., Kanellopoulos, A., Petrou, M., Savva, P. and Mina, A. Development of a new Ultra High Performance Fibre Reinforced Cementitious Composite (UHPFRCC) for impact and blast protection of structures. Journal of Construction and Building Materials, 95, 2015, pp. 667-674.

Nicolaides, D., Kanellopoulos, A. and Petrou, M. Experimental field investigation of impact and blast load resistance of Ultra High Performance Fibre Reinforced Cementitious Composites (UHPFRCCs). Journal of Construction and Building Materials, 95, 2015, pp. 566-574.

Nicolaides, D., Kanellopoulos, A., Petrou, M. and Soutsos, M. Mix Design, Mechanical Properties and Impact Resistance of UHPFRCCs. Proceedings of the 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting, Cape Town, South Africa, September, 2012.

Mao, L., & Barnett, S. J. (2017). Investigation of toughness of ultra high performance fibre reinforced concrete (UHPFRC) beam under impact loading. International Journal of Impact Engineering, 99(1), 26-38.

Mao, L., Barnett, S. J., Tyas, A., Warren, J., Schleyer, G. K., & Zaini, S. S. (2015). Response of small scale ultra high performance fibre reinforced concrete slabs to blast loading. Construction & Building Materials, 93(9), 822-830.

Barnett, S. J., Millard, S. G., Tyas, A., & Schleyer, G. K. (2010). Blast tests of ultra high performance fibre reinforced concrete panels. Proceedings of the Institution of Civil Engineers: Construction Materials, 163(3), 127-129.

Frederick University, Department of Civil Engineering, 7 Yianni Frederickou Street, Pallouriotissa, 1036 Nicosia, Cyprus.

Electrical Engineering and Electronics, University of Liverpool, Liverpool L69 3BX.

School of Civil Engineering and Surveying, University of Portsmouth, Portsmouth, Hampshire PO1 2UP.

School of Physics, Engineering & Computer Science, University of Hertfordshire, Hatfield AL10 9AB.

This project aims to address the following SDGs:

Goal 9 - Industry, Innovation and Infrastructure

This will be achieved by providing an impact resistant rainscreen façade for buildings.

Keywords associated with the Research

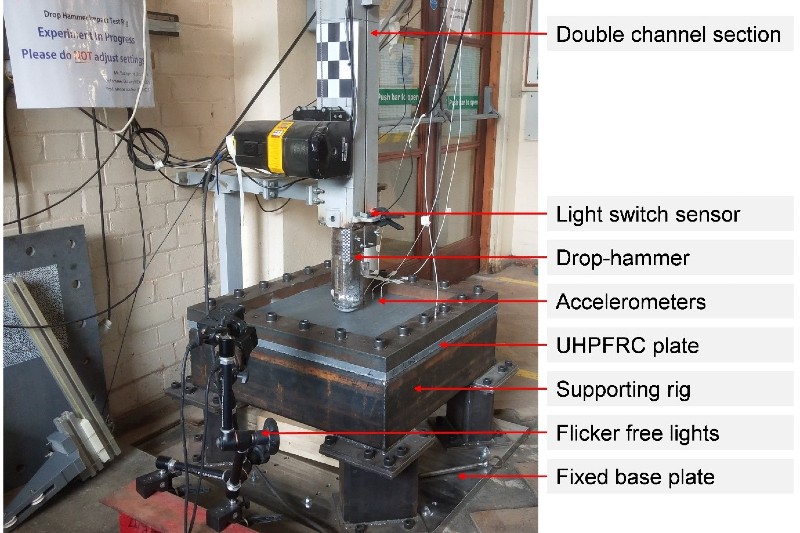

Ultra high performance fibre reinforced concrete, impact loading, abnormal loading, accidental loading, numerical modelling, drop hammer test rig.

Contact Details / Social Media

Marios Soutsos

Professor of Structures/Materials

School of Natural and Built Environment

Queen's University

David Keir Building

Stranmillis Road

Belfast BT9 5AG

Tel: +44 (0)28 9097 4023

Fax: +44 (0)28 9097 4278