Engineers develop device that could radically reduce risks of treating coronary heart disease

A plastic device that could radically reduce the risks and complications of treating coronary heart disease, is being co-developed by scientists at Queen’s University Belfast.

The researchers are working as part of a national project, which is being led by the University of St Andrews, and also includes experts from the University of the Highlands and Islands, the Manufacturing Technology Centre and 5D Health Protection Group. The team has been awarded funding of nearly £1m by the Engineering and Physical Sciences Research Council (EPSRC).

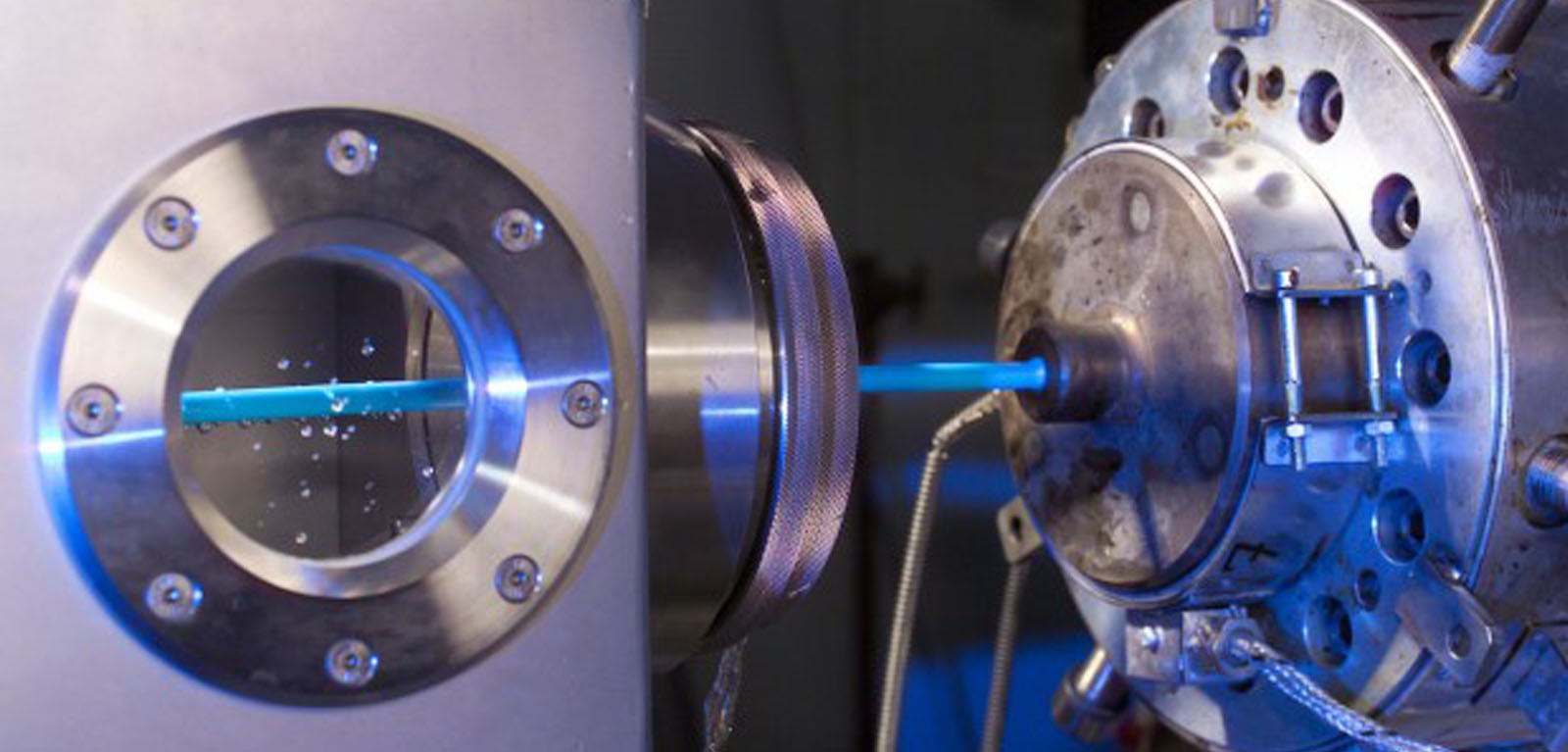

The device, which looks just like the inside tube of a pen, contains an additive which releases nitric oxide (NO) into the body and relaxes the arteries. This can help to prevent problems such as blood clotting and spasm which often occur when medical devices are inserted into arteries – one of the biggest complications in treating the condition.

The additive was first created by chemists at the University of St Andrews and is now being developed by St Andrews spin out company Actiframe. The engineers at Queen’s have been developing the plastic tube that will release the additive.

Dr Bronagh Millar from the Polymer Process Research Centre, based within the School of Mechanical and Aerospace Engineering, is part of the research team at Queen’s. She comments: “The team of engineers at Queen’s are working in a very unique facility for a university. It’s essentially a factory floor, which has state-of-the-art equipment that allows us to create this prototype which could reduce the risks and complications of treating coronary heart disease.

“Coronary heart disease is the leading cause of death globally – more than nine million people die each year and the disease costs the UK economy billions in healthcare costs and productivity losses. These next generation devices will help drive down these costs by reducing both the procedural time and length of hospital stay post treatment."

Dr Stewart Warrender, Senior Research Fellow in the School of Chemistry at the University of St Andrews and EPSRC Project Manager, said: “This exciting project lays the essential groundwork for creating prototype devices for use in future clinical trials. It will bring the positive impact these materials can make on our lives much closer to realisation.”

The collaboration brings together chemists, biomedical scientists, engineers, clinicians and industry experts from across the UK, and is supported by the Life Science division of Lubrizol.

Actiframe is a newly formed company which aims to provide NO-releasing technology to medical device manufacturers.

The ESPRC is one of the main funding bodies for engineering and physical sciences research in the UK and is part of UK Research and Innovation, a new body which works in partnership with universities, research organisations, businesses, charities, and government to create the best possible environment for research and innovation to flourish.

Dr Bronagh Millar

Media

For further information, please contact Emma Gallagher, Queen's University Communications Office, emma.gallagher@qub.ac.uk