Case Studies

“There are huge benefits to be gained [from KTPs]. The academics at Queen’s have a great understanding of what KTP involves and have a particular respect for the commercial requirements of the company", Gareth Robinson, Chief Engineer for Hydraulics

CP Cases Ltd, a London based leader in protective case manufacturing, partnered with Queen’s through a KTP to enhance their rotational moulding processes. This collaboration has significantly improved their operations and efficiency.

A Knowledge Transfer Partnership with Queen's Business School enabled Green Lizard Technologies Ltd to develop a bespoke business model, improving decision-making and resource prioritisation, leading to more confident and efficient decision-making.

Partnership with Queen's enables Card Group, a Belfast-based market research company to develop a groundbreaking model that enhances market insights by combining advanced statistical methods with cutting-edge technology.

Hear how a KTP project with Queen's helped Four Dee (NI) improve productivity, gain a competitive advantage and business growth by introducing robotic welding and automated processes.

The KTP with Queen's enabled Colloide to trial and test a new Anaerobic Digestion system, growing their innovative technology in a new market.

A Management KTP (mKTP) with Queen's Management School has helped SDG to restructure the business and create a culture of innovation.

Terumo BCT, a global leader in healthcare products collaborates with School of Pharmacy to create innovative medical liquid bags that are more sustainable, cost effective and have an extended shelf life.

A pioneering collaboration between Bia Analytical, and Queen’s University Belfast is revolutionising the food industry by integrating cutting-edge techniques from statistics, machine learning, and computer science.

AKT2I Partnership between Queen’s University Belfast & SDG Construction Technology Ltd delivers innovation in supply management to support data-driven decision making.

Dr Ali Aravand is a lecturer in the School of Mechanical and Aerospace Engineering since 2019. Since his initial involvement in KTP, Ali recommends the programme and the KTP Office to academic colleagues across Queen's.

Dr Lisa McFetridge is a senior lecturer in the School of Mathematics and Physics. She first became involved in a KTP project in 2017, and has made the journey from supporting another academic to

Professor Sonebi shares how the experience he gains from KTP projects contributes to his remarkable publications track record, his research work more broadly, and sharing knowledge.

Professor Su Taylor has been involved with KTPs from almost the beginning of her career at Queen’s.

Andrew Grounds, KTP Associate and Paul Roberts, CEO discuss how this KTP collaboration with Queen's University Belfast has changed the social enterprise for the better, now operating both more efficiently and effectively.

A KTP project with Queen's University Belfast enables Moore Concrete to enhance efficiency in pre-cast concrete production for marine infrastructure and sea defences, reducing carbon footprint.

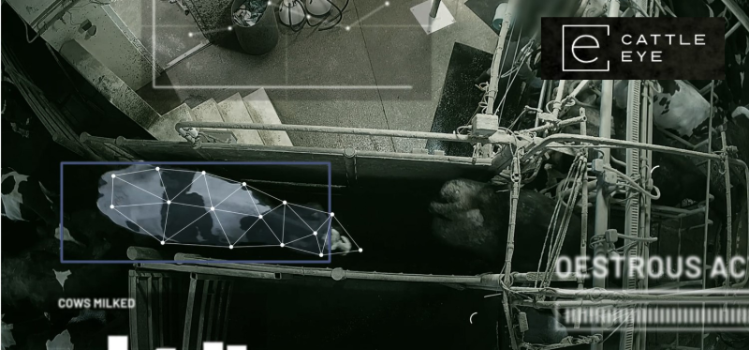

Knowledge Transfer Partnership between Queen's and Cattle Eye is unleashing cow's potential with autonomous video monitoring.

New software to tackle cybersecurity risks increased by remote working has been developed through a partnership between Queen’s University Belfast and Belfast-based tech company Ampliphae.

Using data analysis technology to give motor insurance underwriters a clearer driver risk profile.

Andor Technology founder, Hugh, shares how his experience with Queen’s University and KTP helped shape Cirdan's latest venture in medical imaging.

Q&A in embedding new expertise that will help this successful snack food packaging and production company branch out into process

Ken and Mark discuss their journey, from the decision to pursue a KTP to the significant impact it has had on their practice, positioning Ostick and Williams as a leader in innovative architectural solutions and enhancing their market standing.

Q&A with Smiths Engineering Managing Director, Darwin Smith, Production Manager, Greg Crawford & KTP Associate Barry Lynam